CEPCI Lab & Technical Division Develops Pollution Control System for Cashew Factories

The CEPCI Lab & Technical Division, Kollam, Kerala has developed and designed a Pollution Control System for controlling the effluents emitted from the traditional “Drum Roasting” process in cashew factories. The system is designed to remove heavy carbon particles as well as polluting gases generated during the conventional drum roasting process.

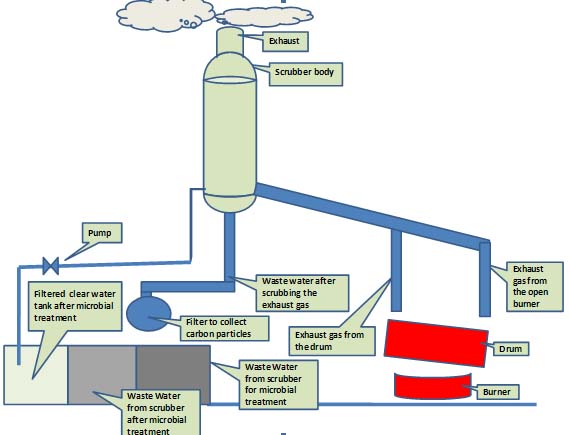

The system consists of a Gas Scrubber and a Biological Engine (see illustration – fig 1). In the scrubber, the undesirable components of the flue gasses are absorbed in water and removed. The stay time of the gases in the scrubber is approximately 2 to 3 seconds.

Gas Scrubber

Conventionally, the smoke generated from the fire below the roasting drum is carried up by draught force to the top of a 40m tall chimney and just dispersed into the atmosphere. The new system is to be installed at a height of 25 m from the ground level as an offshoot of the existing chimney. The scrubber is 10 m tall and within which are fitted three different types of nozzles of different diameters in a spiral arrangement. The lower nozzles spray comparatively more volumes of water in larger particles. The nozzles in the progressive higher levels spray water in finer particle sizes and in lesser volumes. The nozzles in the topmost level will have the least volume and finest spray.

The water spray from the lower row of nozzles carries away bigger particles and water soluble chemical pollutants while the water from the next higher row of nozzles brings down smaller particles along with still un-dissolved chemical pollutants. The fine spray from the topmost row of nozzles carries away almost all the remaining finer particles from the smoke. The extended exhaust tube of the scrubber lets out just clean steam (instead of carbon laden smoke), which is non-polluting. The outlet water from the scrubber containing carbon particles and dissolved chemicals are settled, filtered and re-cycled. The sulfate and nitrate content of the water in the collecting tank after part filtration has been analyzed and found to be well within the accepted limits for reusing. The water would need to be replaced with fresh water every 2 to 3 days.

Biological Engine

In the Biological Engine, the absorbed pollutants in the water are decomposed biologically. The purified water is recycled to the scrubber where it absorbs the pollutants again. Biologically degradable hydrocarbons are converted into H2O and CO2. The non-degradable hydrocarbons remain in the water. Components such as H2S and NH3 are converted into their respective sulfates and nitrates. To keep the salinity and the non-degradable KWS within acceptable levels, regular aeration/ventilation is needed. This can be carried out either by conduction or by means of fixed ventilation. The degree of ventilation depends on the finished gas composition

As is known, the roasting of raw cashew nuts is carried out in a manually rotated open drum of 60 cm dia. and 2.5 m length, with an inclination to facilitate the flow of the material from inlet to outlet by rotation of the drum and gravity. During the “roasting” process, the Cashew Nut Shell Liquid (CNSL) in the cashew nut (calorific value 6000 KCal/kg) catches fire spontaneously and the nut shells get roasted. The hot gases from the inlet of the drum are discharged into atmosphere by a natural draft stack of about 40m height. The cashew nuts in burning state are discharged at the outlet of the drum and quenched immediately with spray of water to prevent over-roasting. The water consumption by quenching process is in the range of 14 – 21 liters per 100 kg of nut roasted. The ash generated from the combustion of roasted shells burnt for the start-up process is sprinkled on the wet nuts to prevent clumping. The quench water containing ash and CNSL is collected in an oil trap and after biological degradation, can be discharged into the ground as harmless wastewater. The water vapor and fumes generated while quenching are discharged by independent short vents connected to the dog-house. In some units, these vents are also connected to the main chimney.

The technology is available for sale with the CEPCI Laboratory and Technical Division. For details, please contact:

The Principal Scientist and Head,

CEPCI Laboratory and Technical Division,

CASHEW BHAVAN, Mundakkal, Kollam 691 001

Kerala, INDIA

Phone No. 0474 – 2742704, 2761003, Mob. 9895528698

Email: cepclab@cashewindia.org

vppotty@yahoo.com